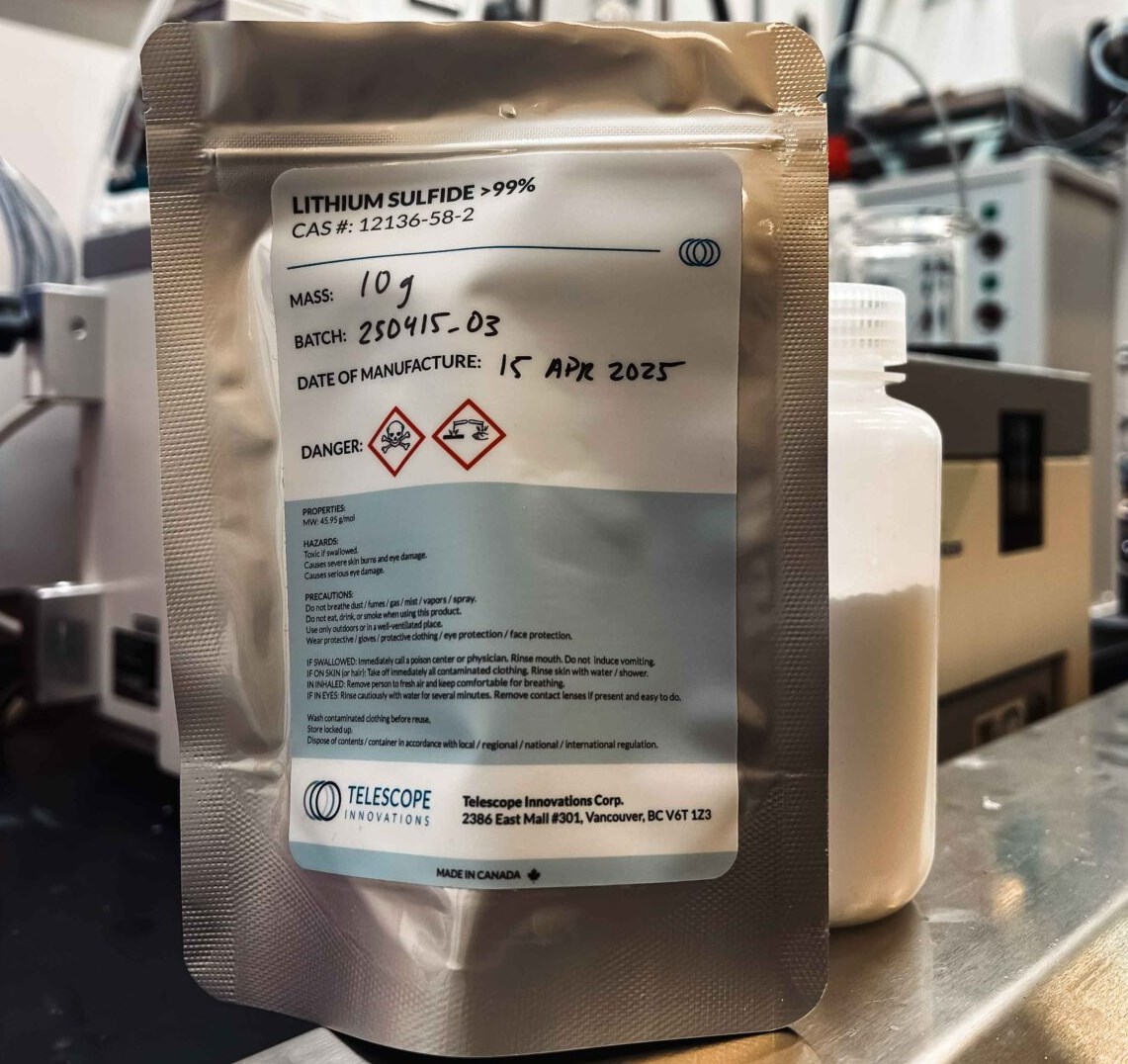

Solid-state batteries are poised to become the next big thing in energy storage for electric vehicles and portable electronics. However, their adoption has been hindered by high production costs. Enter Standard Lithium and Telescope Innovations, two Canadian companies that have introduced an innovative production method known as DualPure. This cutting-edge process significantly reduces the costs associated with manufacturing solid-state batteries by transforming lithium chemicals into high-purity lithium sulfide (Li₂S).

Smart chemistry instead of high temperature: Traditional methods for producing lithium sulfide require high temperatures, typically over 500°C, and demand high purity raw materials. This drives up costs and limits scalability. In contrast, the DualPure process operates below 100°C, drastically cutting energy consumption. It is versatile enough to utilize a variety of inputs, such as lower-quality lithium carbonate or hydroxide, making the production process both cheaper and safer.

The proprietary technology developed by Telescope Innovations ensures a consistent and reliable extraction of high purity lithium sulfide from lithium carbonate and hydroxide. This breakthrough is a game-changer for the industry, allowing manufacturers to reduce costs and expand production capabilities.

The lithium used in this innovative process is sourced from Standard Lithium’s pilot plant in Arkansas. The initial batches of lithium sulfide produced through this method have now been shipped to battery manufacturers across Asia and North America. These shipments represent the first industrial-scale tests of the new production process.

Unlike conventional lithium-ion batteries, solid-state batteries feature a solid electrolyte instead of a liquid one, resulting in higher energy density, faster charging, and a significantly reduced risk of fire. The previously high production costs and challenges of obtaining lithium sulfide were major bottlenecks in their widespread adoption. The DualPure process is set to overcome these hurdles, thanks to its ability to work with less pure inputs, its low-temperature operation, and its minimized requirement for complex equipment. This breakthrough enables scalable lithium sulfide supply chains, crucial for the mass production of solid-state batteries.

As leading companies like Toyota, Panasonic, and CATL race to commercialize solid-state technology, analysts predict a robust annual growth in demand for lithium sulfide, estimated between 50-67 percent over the coming years.

SİGORTA

8 saat önceSİGORTA

15 saat önceBİLGİ

4 gün önceSİGORTA

4 gün önceBLOG

6 gün önceSİGORTA

9 gün önceSİGORTA

13 gün önceSİGORTA

21 gün önceSİGORTA

21 gün önceBLOG

21 gün önce 1

DJI Mini 5: A Leap Forward in Drone Technology

19621 kez okundu

1

DJI Mini 5: A Leap Forward in Drone Technology

19621 kez okundu

2

xAI’s Grok Chatbot Introduces Memory Feature to Rival ChatGPT and Google Gemini

14016 kez okundu

2

xAI’s Grok Chatbot Introduces Memory Feature to Rival ChatGPT and Google Gemini

14016 kez okundu

3

7 Essential Foods for Optimal Brain Health

12902 kez okundu

3

7 Essential Foods for Optimal Brain Health

12902 kez okundu

4

Elon Musk’s Father: “Admiring Putin is Only Natural”

12756 kez okundu

4

Elon Musk’s Father: “Admiring Putin is Only Natural”

12756 kez okundu

5

Minnesota’s Proposed Lifeline Auto Insurance Program

10636 kez okundu

5

Minnesota’s Proposed Lifeline Auto Insurance Program

10636 kez okundu

Sigorta Güncel Sigorta Şikayet Güvence Haber Hasar Onarım Insurance News Ajans Sigorta Sigorta Kampanya Sigorta Ajansı Sigorta Sondakika Insurance News