Scientists in the United States have made a groundbreaking advancement in hydrogen production by utilizing seawater and recycled aluminum. This innovative process, led by MIT (Massachusetts Institute of Technology) graduate mechanical engineer Aly Kombargi, has the potential to cut the carbon footprint of hydrogen production by up to 90%.

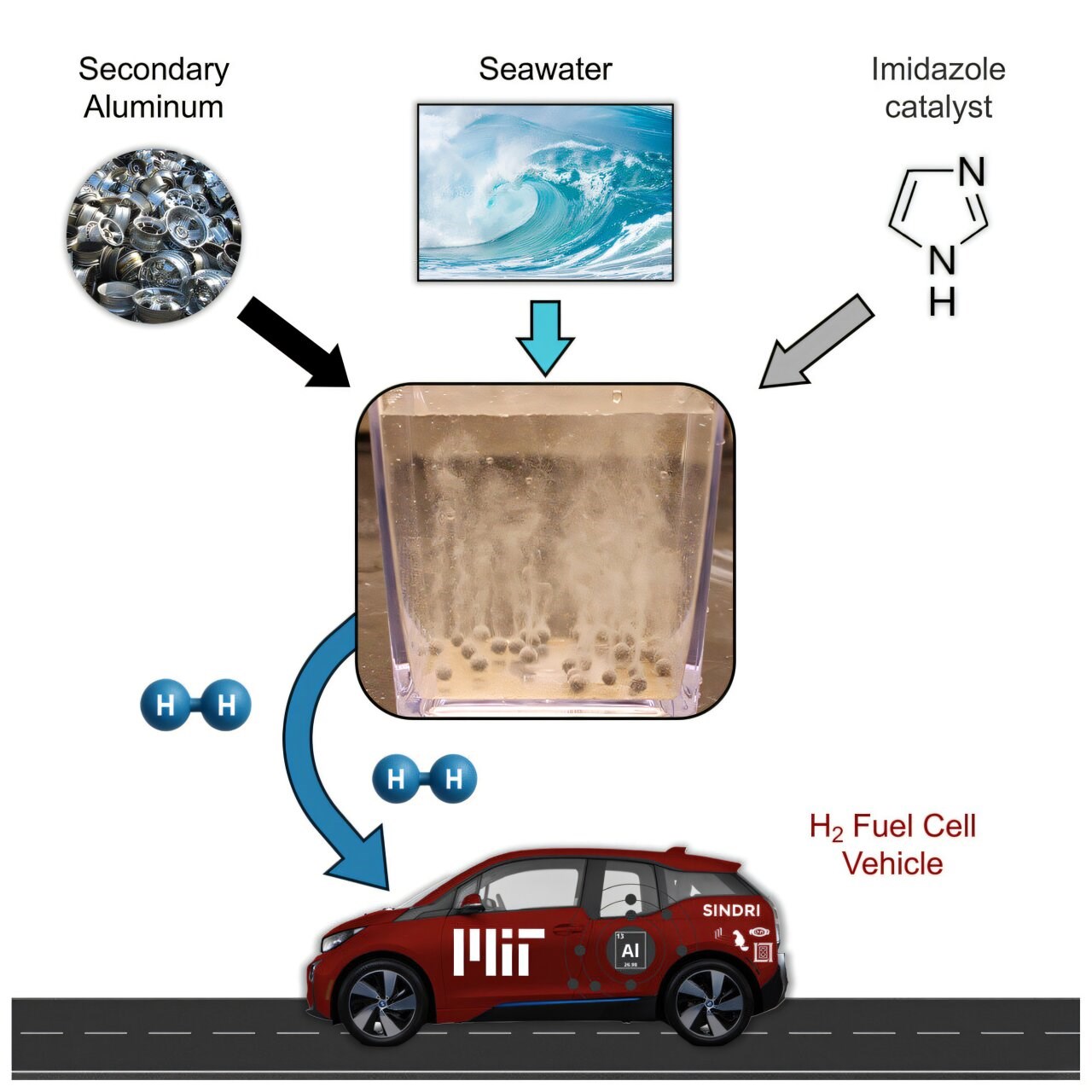

Hydrogen has been heralded as a clean energy source due to its lack of carbon dioxide emissions when utilized. However, the majority of hydrogen today is still sourced from fossil fuels, resulting in approximately 11 kilograms of CO₂ emissions per 1 kilogram of hydrogen produced. This groundbreaking method developed by the MIT team reduces that figure to a mere 1.45 kilograms of CO₂, marking a pivotal step towards sustainable hydrogen production.

The team uses recycled aluminum from everyday beverage cans, combining it with a small quantity of gallium-indium alloy and reacting it with seawater to generate hydrogen gas. Notably, seawater not only initiates this reaction but also aids in precipitating the rare metals employed in the process. These metals can then be efficiently recovered, rendering the process economically and environmentally circular.

Additionally, a valuable by-product called boehmite (also known as bemite or böhmit) is produced. Boehmite finds applications in semiconductor manufacturing and various industrial uses, adding further economic value to the process. The research team employed a comprehensive life cycle analysis tool known as “Earthster” to evaluate the environmental impact, revealing that their method is competitive with green hydrogen derived from renewable sources like solar and wind energy.

The cost of producing 1 kilogram of hydrogen is estimated to be around $9, comparable to existing green hydrogen technologies. According to researchers, a vehicle can travel approximately 100 kilometers on a single kilogram of hydrogen. The potential applications extend beyond land vehicles to include submarine systems, small boats, and autonomous underwater vehicles. The research team is now focused on refining and scaling up this promising process.

OTOMOBİL

6 saat önceTÜKETİCİ KÖŞESİ

11 saat önceTÜKETİCİ KÖŞESİ

11 saat önceSİGORTA

1 gün önceOTOMOBİL

4 gün önceSİGORTA

4 gün önceSİGORTA

4 gün önceSİGORTA

6 gün önceSİGORTA

6 gün önceBİLGİ

6 gün önce 1

DJI Mini 5: A Leap Forward in Drone Technology

20639 kez okundu

1

DJI Mini 5: A Leap Forward in Drone Technology

20639 kez okundu

2

xAI’s Grok Chatbot Introduces Memory Feature to Rival ChatGPT and Google Gemini

14599 kez okundu

2

xAI’s Grok Chatbot Introduces Memory Feature to Rival ChatGPT and Google Gemini

14599 kez okundu

3

7 Essential Foods for Optimal Brain Health

13291 kez okundu

3

7 Essential Foods for Optimal Brain Health

13291 kez okundu

4

Elon Musk’s Father: “Admiring Putin is Only Natural”

13125 kez okundu

4

Elon Musk’s Father: “Admiring Putin is Only Natural”

13125 kez okundu

5

Minnesota’s Proposed Lifeline Auto Insurance Program

11028 kez okundu

5

Minnesota’s Proposed Lifeline Auto Insurance Program

11028 kez okundu

Sigorta Güncel Sigorta Şikayet Güvence Haber Hasar Onarım Insurance News Ajans Sigorta Sigorta Kampanya Sigorta Ajansı Sigorta Sondakika Insurance News