Apple’s latest iPhone 16 series introduced a surprise contender, the iPhone 16e, priced at a competitive $599. Counterpoint Research recently shed light on the component costs of the iPhone 16e, revealing fascinating insights into Apple’s strategic choices.

Apple’s Dominance in Component Manufacturing

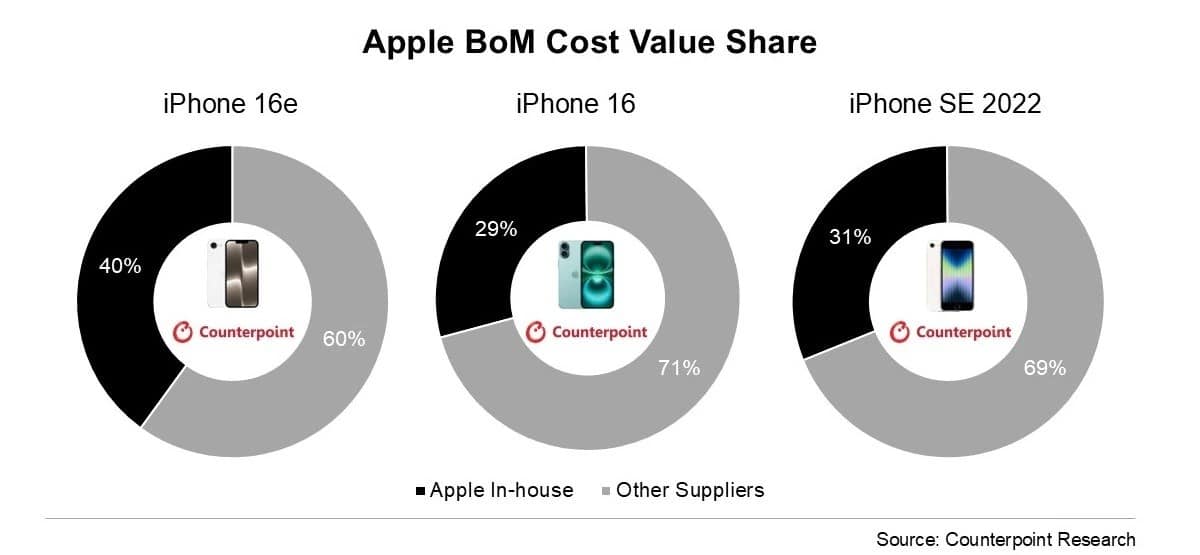

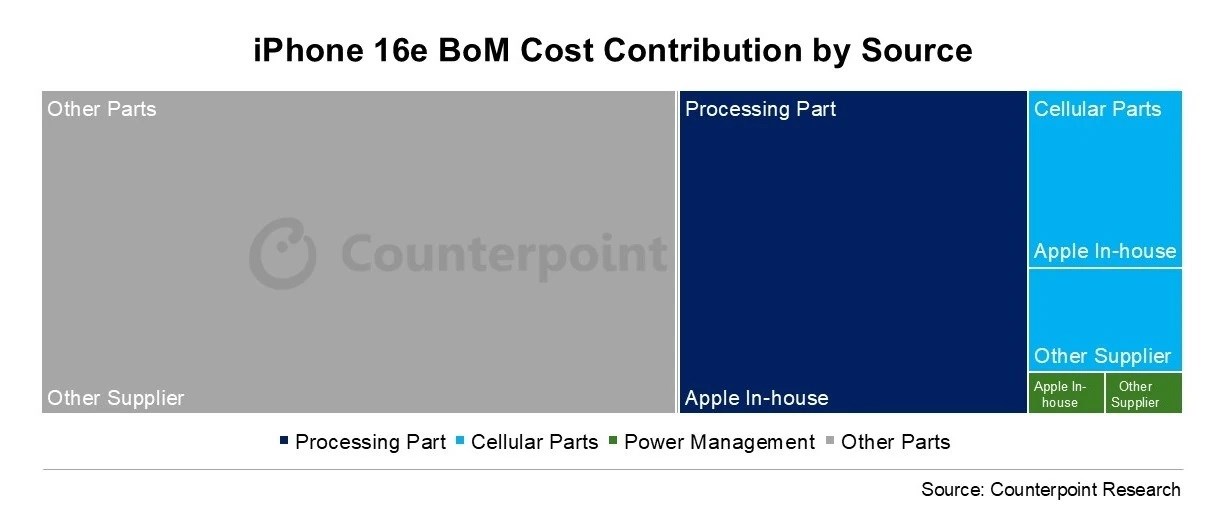

Remarkably, 40% of the components in the iPhone 16e are manufactured in-house by Apple, a notable achievement compared to previous models. For context, the iPhone 16 series ranges between 39% to 71% of Apple-manufactured parts, while the 2022 iPhone SE had a 31% to 69% split between Apple and third-party suppliers. This marks a significant shift towards Apple’s self-reliance in production.

The Game-Changing C1 5G Modem

The reduction in part costs is largely attributed to Apple’s innovative C1 5G modem. This modem allows for a $10 savings per device, which scales impressively when considering Apple’s target to sell 22 million units, culminating in a total savings of $220 million. Although the C1 lacks mmWave support, it provides up to 40% better performance compared to the Snapdragon X71 modem used in the iPhone 16 lineup. Its design spans the 4nm and 7nm manufacturing processes, ensuring energy-efficient performance.

Simplifications for Cost Efficiency

Apple’s strategy doesn’t stop at the modem. The iPhone 16e features a simplified design with a single rear camera, and omits hardware like MagSafe, further reducing overall production costs. These strategic simplifications are crucial in maintaining the device’s affordability without compromising on quality.

OTOMOBİL

3 saat önceSİGORTA

5 saat önceSİGORTA

5 saat önceSİGORTA

2 gün önceSİGORTA

2 gün önceBİLGİ

2 gün önceBİLGİ

2 gün önceSİGORTA

3 gün önceSİGORTA

3 gün önceSİGORTA

3 gün önce 1

DJI Mini 5: A Leap Forward in Drone Technology

20612 kez okundu

1

DJI Mini 5: A Leap Forward in Drone Technology

20612 kez okundu

2

xAI’s Grok Chatbot Introduces Memory Feature to Rival ChatGPT and Google Gemini

14582 kez okundu

2

xAI’s Grok Chatbot Introduces Memory Feature to Rival ChatGPT and Google Gemini

14582 kez okundu

3

7 Essential Foods for Optimal Brain Health

13285 kez okundu

3

7 Essential Foods for Optimal Brain Health

13285 kez okundu

4

Elon Musk’s Father: “Admiring Putin is Only Natural”

13119 kez okundu

4

Elon Musk’s Father: “Admiring Putin is Only Natural”

13119 kez okundu

5

Minnesota’s Proposed Lifeline Auto Insurance Program

11023 kez okundu

5

Minnesota’s Proposed Lifeline Auto Insurance Program

11023 kez okundu

Sigorta Güncel Sigorta Şikayet Güvence Haber Hasar Onarım Insurance News Ajans Sigorta Sigorta Kampanya Sigorta Ajansı Sigorta Sondakika Insurance News